W-type silicon-molybdenum rod

W-type silicon molybdenum rod: This specification is generally used in a horizontal position. Due to the more extensive distribution of the heating ends in the electric furnace, it has high thermal efficiency and saves costs. The W-type heating element is suitable for electric furnaces with a lower chamber height, providing greater economic benefits, as fewer elements are required per unit length in each chamber, resulting in less heat loss at the cold end, significantly improving thermal efficiency.

Classification:

keyword: W-type silicon-molybdenum rod

Share:

Product Description

W-shaped silicon molybdenum rod: This specification is generally used in a horizontal position. Due to the more distributed heating ends in the electric furnace, the thermal efficiency is high, and it saves costs. The W-shaped heating element is suitable for electric furnaces with a lower chamber height, providing greater economic benefits, as fewer elements are required per unit length in each chamber, resulting in less heat loss at the cold end, significantly improving thermal efficiency.

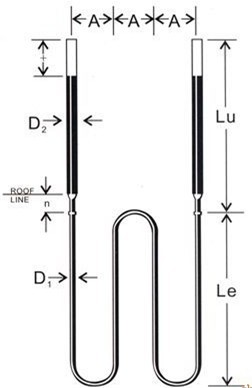

Customers need to provide parameters such as the diameter of the heating end, length of the heating end, length of the cold end, and center distance when customizing products.

Material Grade: 1700, 1800

Diameter: D1/D2, mm/mm

Hot zone length: Le, mm

Cold end length: Lu, mm

Examples

W-shaped, Material Grade 1700

D1=6mm, D2=12mm, Le=300mm, Lu=250mm, A=50mm

Specify as:

Jinyu Super MS17, W-shaped, 6/12×300×250×50

Previous Page

Next Page

Previous Page

Next Page

Related Products

Equal diameter silicon carbide rods are alternative products to coarse end silicon carbide rods, featuring advantages such as low end resistance, long service life, and energy saving. They are commonly used in industries such as rare earth phosphors, electronics, magnetic materials, powder metallurgy, and precision casting, serving as heating elements for push plate furnaces, mesh belt furnaces, trolley furnaces, and box furnaces.

U-shaped silicon molybdenum rod

U-shaped silicon molybdenum rod: The double-handled U-shaped design component is the most commonly used type. The heating end is welded to the cold end terminal part, while the cold end diameter is twice that of the heating end diameter. This specification is the most commonly used specification and is generally used for vertical suspension.

Straight rod type silicon carbide rod

Equal diameter silicon carbide rods are alternative products to coarse end silicon carbide rods, featuring advantages such as low end resistance, long service life, and energy saving. They are commonly used in industries such as rare earth phosphors, electronics, magnetic materials, powder metallurgy, and precision casting, serving as heating elements for push plate furnaces, mesh belt furnaces, car furnaces, and box furnaces.

The coarse end silicon carbide rod is an electric heating element composed of a hollow tubular heating part and a thickened end. The material of the element is hard and brittle, resistant to rapid cooling and heating, and does not deform at high temperatures.

Online message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!