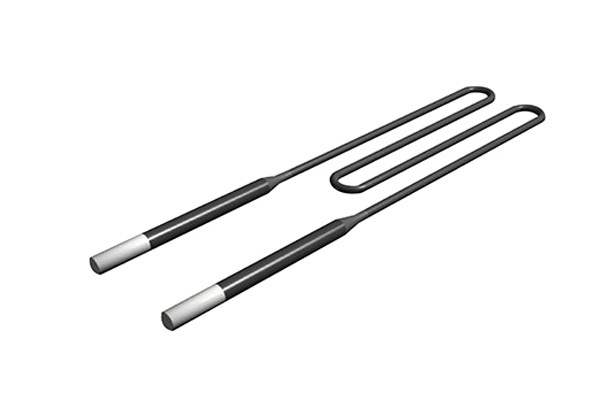

U-shaped silicon molybdenum rod

U-shaped silicon molybdenum rod: The double-handled U-shaped design component is the most commonly used type. The heating end is welded to the cold end terminal part, while the cold end diameter is twice that of the heating end diameter. This specification is the most commonly used specification and is generally used for vertical suspension.

GM-L type silicon-molybdenum rod

Silicon-molybdenum rod resistive heating elements are high-temperature, oxidation-resistant resistive heating components made from molybdenum disilicide. When used in a high-temperature oxidizing atmosphere, a bright and dense quartz (SiO2) glass film forms on the surface, which protects the inner layer of the silicon-molybdenum rod from further oxidation. Therefore, silicon-molybdenum rod elements have unique high-temperature oxidation resistance.

W-type silicon molybdenum rod: This specification is generally used in a horizontal position. Due to the more extensive distribution of the heating ends in the electric furnace, it has high thermal efficiency and saves costs. The W-type heating element is suitable for electric furnaces with a lower chamber height, providing greater economic benefits, as fewer elements are required per unit length in each chamber, resulting in less heat loss at the cold end, significantly improving thermal efficiency.

Contact Information

E-mail:boxin880@163.com

Phone: +86-371-62727333

Business Phone:+86-16603975777

Complaint Telephone:+86-18638219322

Address: No. 2-13 Yudu Street, Dengfeng City, Henan Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

All rights reserved©2025 Zhengzhou Barsic High Temperature Material Co., Ltd. www.300.cn SEO Privacy Policy