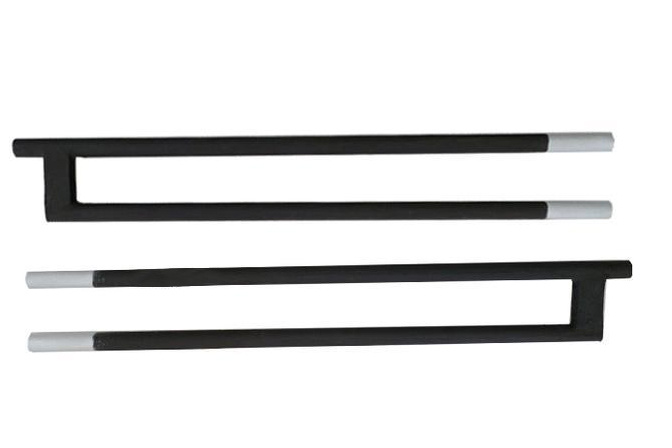

Equal diameter silicon carbide rods are alternative products to coarse end silicon carbide rods, featuring advantages such as low end resistance, long service life, and energy saving. They are commonly used in industries such as rare earth phosphors, electronics, magnetic materials, powder metallurgy, and precision casting, serving as heating elements for push plate furnaces, mesh belt furnaces, trolley furnaces, and box furnaces.

U-shaped silicon molybdenum rod

U-shaped silicon molybdenum rod: The double-handled U-shaped design component is the most commonly used type. The heating end is welded to the cold end terminal part, while the cold end diameter is twice that of the heating end diameter. This specification is the most commonly used specification and is generally used for vertical suspension.

Straight rod type silicon carbide rod

Equal diameter silicon carbide rods are alternative products to coarse end silicon carbide rods, featuring advantages such as low end resistance, long service life, and energy saving. They are commonly used in industries such as rare earth phosphors, electronics, magnetic materials, powder metallurgy, and precision casting, serving as heating elements for push plate furnaces, mesh belt furnaces, car furnaces, and box furnaces.

The coarse end silicon carbide rod is an electric heating element composed of a hollow tubular heating part and a thickened end. The material of the element is hard and brittle, resistant to rapid cooling and heating, and does not deform at high temperatures.

U-shaped silicon carbide rods usage industry and precautions. The U-shaped silicon carbide rod consists of two silicon carbide rods of equal diameter sharing one cold end. The U-shaped silicon carbide rod allows for the power supply line to be connected at one end of the furnace, with a heating surface temperature of 1500. It is mainly used in kilns with high furnace temperatures and high requirements for temperature uniformity.

The gun-type silicon carbide rod is improved from the U-shaped silicon carbide rod, extending a length of 40-60 at one end of the U shape, serving as a support for the rod body. This type of rod is mainly used in the glass bottle manufacturing industry, in conjunction with five-segment rods (such as dual heating elements of the same diameter). The five-segment rod is used to heat the glass material channel, while the gun rod is used to heat the material basin.

The W-shaped three-phase rod is composed of one shared silicon carbide rod connecting one end of three high-purity silicon carbide rods. The joint is also made of silicon carbide, and the structure of the rods is completely identical, used for horizontal installation in float glass electric tanks. The three-phase silicon carbide rods can be directly connected to a three-phase power supply and can be wired unidirectionally at the furnace top.

H-shaped silicon carbide rods (GDH): commonly used for heating and insulation in the feeding channels and trough sections of the glass industry. The electrical performance of silicon carbide rods is that they are a nonlinear resistive body, with a relatively large resistance dispersion at room temperature.