Silicon carbide ceramics have excellent properties such as high hardness, high thermal conductivity, good high-temperature creep resistance, oxidation resistance, and corrosion resistance, and are widely used in fields such as chemical heat exchange, chemical micro-reactors, and high-temperature flue gas waste heat recovery.

The actual density of silicon carbide ceramics exceeds 98% of the theoretical density of silicon carbide, and silicon carbide is a seal without the use of any impregnating agents. Its hardness is 50% higher than that of tungsten carbide (hard alloy), thus it possesses super wear resistance and complete impermeability even under extreme high temperatures and pressures, and it does not contaminate the medium in high purity applications and is chemically inert. It is widely used in the pharmaceutical field, such as in microchannel continuous reaction plates, reaction tubes, shell-and-tube heat exchangers and condensers, and block-type reactors.

Silicon carbide ceramics, with their high mechanical strength, wear resistance, high temperature resistance, strong acid and alkali corrosion resistance, oxidation resistance, and ability to withstand extreme cold and heat, have been widely used in the fields of oil and gas extraction, petrochemical smelting, and fine chemicals. Applications include ceramic filter sand pipes, wear-resistant lining pipes, chemical heat exchange tubes, heat exchange plates, microchannel reaction plates, sealing rings, shaft sleeves, ceramic valve cores, and ceramic pump impeller components.

Amorphous alloys are formed due to ultra-rapid cooling solidification. When the alloy solidifies, the atoms do not have enough time to arrange themselves in an orderly crystalline structure, resulting in a solid alloy with a long-range disordered structure, without the presence of grains and grain boundaries found in crystalline alloys. This is referred to as amorphous alloy and is considered a revolution in materials science.

Powder metallurgy is a process technology for producing metal powders or using metal powders (or mixtures of metal powders and non-metal powders) as raw materials, which involves shaping and sintering to manufacture metal materials, composite materials, and various types of products.

Military industrial bulletproof

Ceramic materials, as a key member of non-metallic materials, possess a large number of highly attractive properties, such as good mechanical properties and electrochemical performance, low thermal conductivity, dense and uniform structure, wear resistance, and corrosion resistance, etc.

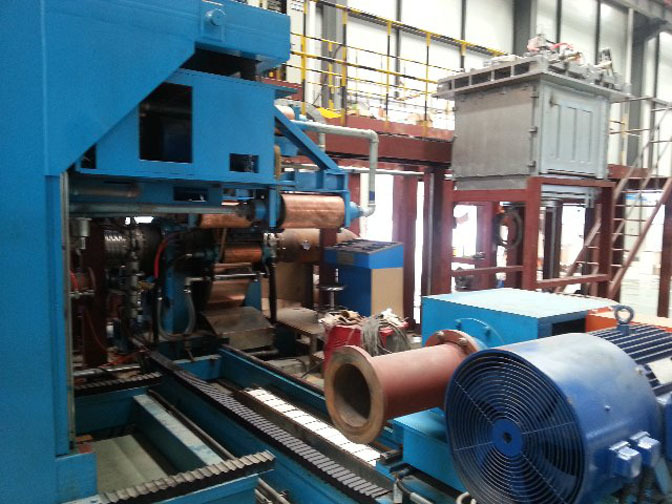

Material: Reaction-sintered silicon carbide/silicon nitride bonded silicon carbide