Military industrial bulletproof

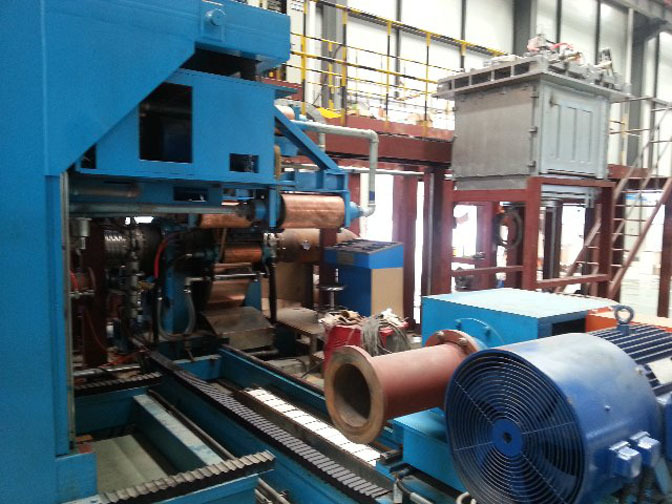

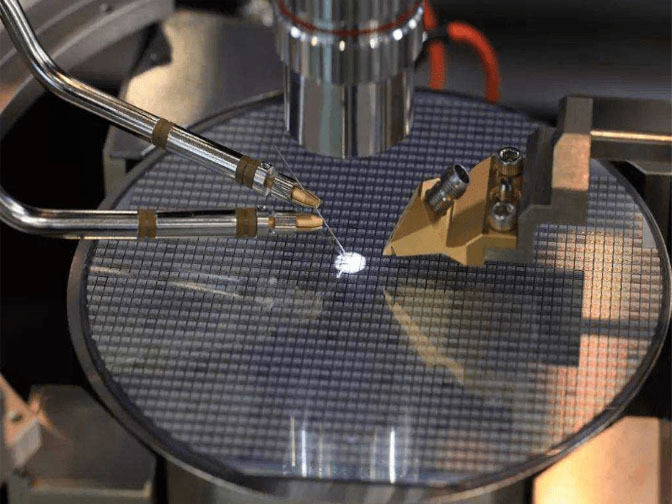

Ceramic materials, as a key member of non-metallic materials, possess a large number of highly attractive properties, such as good mechanical properties and electrochemical performance, low thermal conductivity, dense and uniform structure, wear resistance, and corrosion resistance, etc. The high specific stiffness, high specific strength, and chemical inertness in complex environments of ceramic materials make their application in armor systems very promising, and they have been widely used in protective armor for bulletproof vests, special vehicles, naval ship armor protection, and armed helicopters.

Currently, commonly used armor ceramic materials mainly include boron carbide (B4C), silicon carbide (SiC), and aluminum oxide (Al2O3).

Military industrial bulletproof

Ceramic materials, as a key member of non-metallic materials, possess a large number of highly attractive properties, such as good mechanical properties and electrochemical performance, low thermal conductivity, dense and uniform structure, wear resistance, and corrosion resistance, etc. The high specific stiffness, high specific strength, and chemical inertness in complex environments of ceramic materials make their application in armor systems very promising, and they have been widely used in protective armor for bulletproof vests, special vehicles, naval ship armor protection, and armed helicopters.

Currently, commonly used armor ceramic materials mainly include boron carbide (B4C), silicon carbide (SiC), and aluminum oxide (Al2O3).