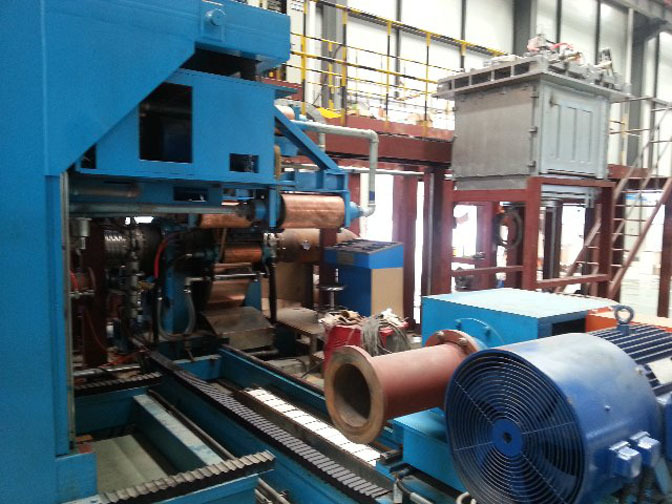

Rare earth powder metallurgy

Material: Reactive Sintering/Pressureless Sintering Silicon Carbide

Powder metallurgy is a process technology for producing metal powders or using metal powders (or mixtures of metal powders and non-metal powders) as raw materials, which are shaped and sintered to manufacture metal materials, composite materials, and various types of products. The powder metallurgy method has similarities with ceramic production, both belonging to powder sintering technology. Therefore, a series of new powder metallurgy technologies can also be used for the preparation of ceramic materials. Due to the advantages of powder metallurgy technology, it has become the key to solving new material problems and plays a crucial role in the development of new materials.

Powder metallurgy includes powder production and products. Among them, powder production is mainly a metallurgical process, which matches the literal meaning. However, powder metallurgy products often go far beyond the scope of materials and metallurgy, often involving multiple disciplines (materials and metallurgy, mechanics, etc.). Especially modern metal powder 3D printing integrates mechanical engineering, CAD, reverse engineering technology, layered manufacturing technology, CNC technology, materials science, and laser technology, making powder metallurgy product technology a modern comprehensive technology that spans more disciplines.

Powder metallurgy has unique chemical compositions and mechanical and physical properties that cannot be obtained by traditional casting methods. By using powder metallurgy technology, it is possible to directly produce porous, semi-dense, or fully dense materials and products, such as oil-containing bearings, gears, cams, guide rods, tools, etc., which is a process with little to no cutting.

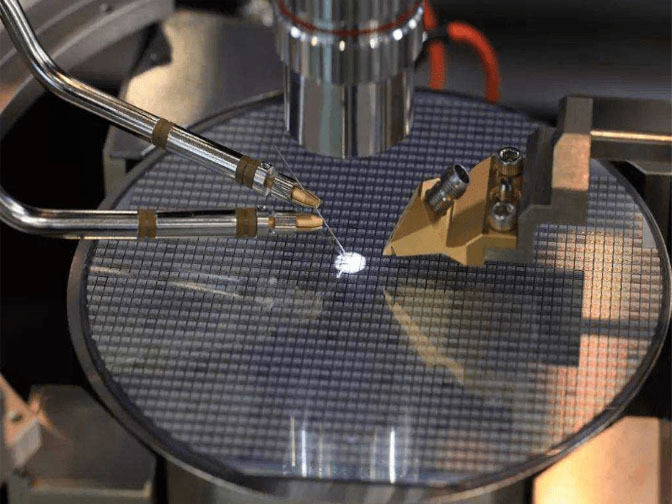

Rare earth powder metallurgy

Material: Reactive Sintering/Pressureless Sintering Silicon Carbide

Powder metallurgy is a process technology for producing metal powders or using metal powders (or mixtures of metal powders and non-metal powders) as raw materials, which are shaped and sintered to manufacture metal materials, composite materials, and various types of products. The powder metallurgy method has similarities with ceramic production, both belonging to powder sintering technology. Therefore, a series of new powder metallurgy technologies can also be used for the preparation of ceramic materials. Due to the advantages of powder metallurgy technology, it has become the key to solving new material problems and plays a crucial role in the development of new materials.

Powder metallurgy includes powder production and products. Among them, powder production is mainly a metallurgical process, which matches the literal meaning. However, powder metallurgy products often go far beyond the scope of materials and metallurgy, often involving multiple disciplines (materials and metallurgy, mechanics, etc.). Especially modern metal powder 3D printing integrates mechanical engineering, CAD, reverse engineering technology, layered manufacturing technology, CNC technology, materials science, and laser technology, making powder metallurgy product technology a modern comprehensive technology that spans more disciplines.

Powder metallurgy has unique chemical compositions and mechanical and physical properties that cannot be obtained by traditional casting methods. By using powder metallurgy technology, it is possible to directly produce porous, semi-dense, or fully dense materials and products, such as oil-containing bearings, gears, cams, guide rods, tools, etc., which is a process with little to no cutting.