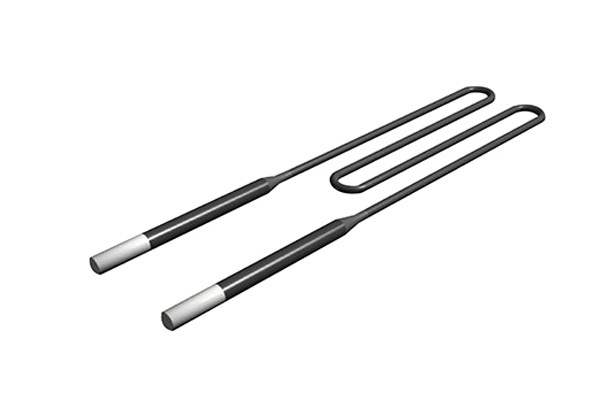

GM-L type silicon-molybdenum rod

Silicon-molybdenum rod resistive heating elements are high-temperature, oxidation-resistant resistive heating components made from molybdenum disilicide. When used in a high-temperature oxidizing atmosphere, a bright and dense quartz (SiO2) glass film forms on the surface, which protects the inner layer of the silicon-molybdenum rod from further oxidation. Therefore, silicon-molybdenum rod elements have unique high-temperature oxidation resistance.

Fixtures, also known as jigs, are devices used in the mechanical manufacturing process to fix the processed object in the correct position.

W-type silicon molybdenum rod: This specification is generally used in a horizontal position. Due to the more extensive distribution of the heating ends in the electric furnace, it has high thermal efficiency and saves costs. The W-type heating element is suitable for electric furnaces with a lower chamber height, providing greater economic benefits, as fewer elements are required per unit length in each chamber, resulting in less heat loss at the cold end, significantly improving thermal efficiency.

Silicon carbide ceramics, with their excellent properties of low friction, high strength, low inertial load, and thermal shock resistance, are used in high-end equipment such as guide rails, bearings, shaft sleeves, wear-resistant rotors, guide wheels, liners, and sandblasting nozzles.

The roller kiln is a type of kiln with high output and low energy consumption. It was initially used in the building ceramics, sanitary ceramics, and daily-use porcelain industries. Due to its many advantages and the development of roller rod materials, such as the emergence of silicon carbide ceramic roller rods, it has started to be used in the lithium battery materials, rare earth, magnetic materials raw materials, electronic powders, and electrical porcelain components industries in the past two years. The appearance of silicon carbide roller rods allows the furnace temperature to reach as high as 1200°C.

Electric heating radiation tubes are devices that consume electrical energy and convert it into thermal energy to heat materials that need to be heated. The electric heating element is enclosed within a protective sleeve, and after being powered, the heat is indirectly radiated to the furnace lining and the workpiece being heated through the sleeve.

Wear-resistant and corrosion-resistant

The inner lining wear-resistant ceramic tile corrugated compensator has efficient heat resistance, wear resistance, mechanical and thermal shock resistance, and is easy to weld and install. It is particularly suitable for material conveying pipelines that experience severe wear and scouring, such as those in industries like coal-fired power generation, metallurgy, coal, and mining.

Energy saving and environmental protection

The desulfurization atomization nozzle made of reaction-sintered silicon carbide (SISIC) has a service life several times to over ten times that of other materials. Reaction-sintered silicon carbide (SISIC) represents a relatively advanced level of materials in the field of desulfurization nozzles.