Amorphous Nanometer

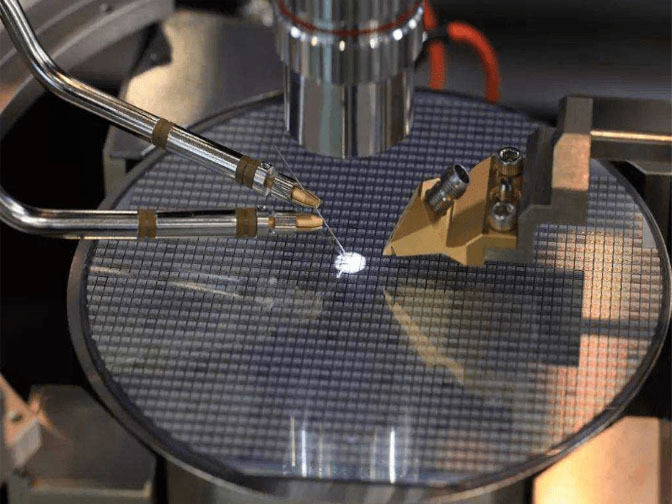

Amorphous alloys are solid alloys obtained due to ultra-rapid cooling solidification, where atoms do not have enough time to orderly arrange into crystals during the alloy solidification process. The resulting solid alloy has a long-range disordered structure, lacking the grains and grain boundaries present in crystalline alloys, and is referred to as amorphous alloy, which is considered a revolution in metallurgical materials science. This type of amorphous alloy possesses many unique properties, such as excellent magnetism, corrosion resistance, wear resistance, high strength, hardness, and toughness, as well as high resistivity and electromechanical coupling performance. Due to its outstanding performance and simple processing, it has become a key focus of research and development in the materials science community both domestically and internationally since the 1980s.

For thousands of years, the metals or alloys used by humans have been materials with crystalline structures, where their atoms are arranged in an orderly manner in three-dimensional space, forming a periodic lattice structure.

Amorphous metals or alloys refer to substances that, when rapidly cooled from a liquid (or gas) state, do not crystallize in time and retain a disordered arrangement of liquid atoms at room temperature or low temperatures. Their atoms no longer grow in a long-range ordered, periodic, and regular arrangement, but exist in a state of long-range disorder. Amorphous ferromagnetic alloys are also known as ferromagnetic metallic glasses or magnetic glasses (Glassy Alloy). For convenience of description, the following will all be referred to as amorphous alloys.

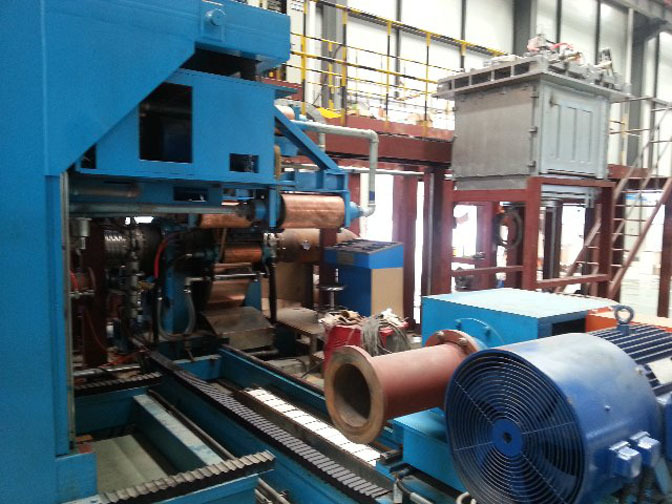

After gaining a preliminary understanding of amorphous alloys, let us look at a very promising application area of amorphous alloys—amorphous transformers. Amorphous alloy iron core transformers are transformers made with a new type of magnetic material—amorphous alloy for the iron core. They reduce no-load losses (referring to the power loss measured in the primary when the secondary of the transformer is open) by about 75% compared to silicon steel sheet iron core transformers, and the no-load current (the current that still exists in the primary when the secondary of the transformer is open, referred to as no-load current) decreases by about 80%. They are currently one of the most ideal energy-saving distribution transformers, especially suitable for areas with low load rates, such as rural power grids and developing regions.

Since 2006, the significant price increase of silicon steel has led to amorphous prices being even lower than silicon steel; at the same time, its energy-saving effects have also received much attention due to the emphasis on energy issues. Amorphous strip materials, due to their lower loss rates, can play a significant role in reducing electricity consumption when used in new types of distribution transformers. As the Chinese transformer market accelerates its development towards amorphous distribution transformers, the market for amorphous strip materials is continuously expanding.

Differences from traditional silicon steel sheets

Unlike traditional silicon steel sheets, amorphous alloys are brittle after stamping and are difficult to form into stacked sheets. Therefore, in practical applications, amorphous alloys often exist in the form of winding processes. In recent years, the use of amorphous soft magnetic materials in motors has also increased, and their excellent energy-saving properties with low iron loss have received widespread attention in the academic community.

Amorphous Nanometer

Amorphous alloys are solid alloys obtained due to ultra-rapid cooling solidification, where atoms do not have enough time to orderly arrange into crystals during the alloy solidification process. The resulting solid alloy has a long-range disordered structure, lacking the grains and grain boundaries present in crystalline alloys, and is referred to as amorphous alloy, which is considered a revolution in metallurgical materials science. This type of amorphous alloy possesses many unique properties, such as excellent magnetism, corrosion resistance, wear resistance, high strength, hardness, and toughness, as well as high resistivity and electromechanical coupling performance. Due to its outstanding performance and simple processing, it has become a key focus of research and development in the materials science community both domestically and internationally since the 1980s.

For thousands of years, the metals or alloys used by humans have been materials with crystalline structures, where their atoms are arranged in an orderly manner in three-dimensional space, forming a periodic lattice structure.

Amorphous metals or alloys refer to substances that, when rapidly cooled from a liquid (or gas) state, do not crystallize in time and retain a disordered arrangement of liquid atoms at room temperature or low temperatures. Their atoms no longer grow in a long-range ordered, periodic, and regular arrangement, but exist in a state of long-range disorder. Amorphous ferromagnetic alloys are also known as ferromagnetic metallic glasses or magnetic glasses (Glassy Alloy). For convenience of description, the following will all be referred to as amorphous alloys.

After gaining a preliminary understanding of amorphous alloys, let us look at a very promising application area of amorphous alloys—amorphous transformers. Amorphous alloy iron core transformers are transformers made with a new type of magnetic material—amorphous alloy for the iron core. They reduce no-load losses (referring to the power loss measured in the primary when the secondary of the transformer is open) by about 75% compared to silicon steel sheet iron core transformers, and the no-load current (the current that still exists in the primary when the secondary of the transformer is open, referred to as no-load current) decreases by about 80%. They are currently one of the most ideal energy-saving distribution transformers, especially suitable for areas with low load rates, such as rural power grids and developing regions.

Since 2006, the significant price increase of silicon steel has led to amorphous prices being even lower than silicon steel; at the same time, its energy-saving effects have also received much attention due to the emphasis on energy issues. Amorphous strip materials, due to their lower loss rates, can play a significant role in reducing electricity consumption when used in new types of distribution transformers. As the Chinese transformer market accelerates its development towards amorphous distribution transformers, the market for amorphous strip materials is continuously expanding.

Differences from traditional silicon steel sheets

Unlike traditional silicon steel sheets, amorphous alloys are brittle after stamping and are difficult to form into stacked sheets. Therefore, in practical applications, amorphous alloys often exist in the form of winding processes. In recent years, the use of amorphous soft magnetic materials in motors has also increased, and their excellent energy-saving properties with low iron loss have received widespread attention in the academic community.