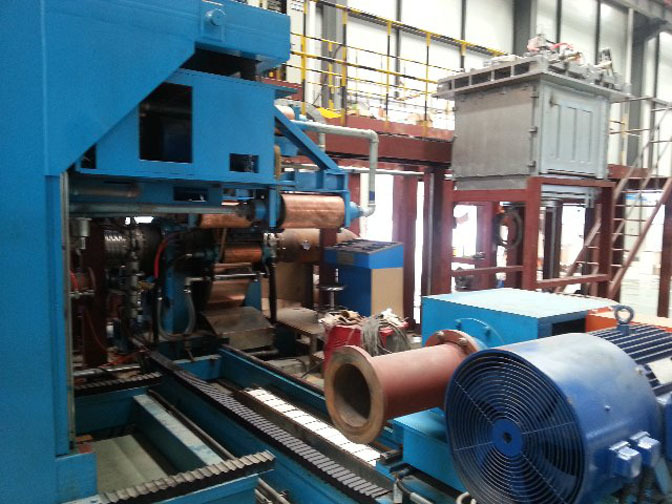

Wear-resistant and corrosion-resistant

Wear-resistant lining for mines

Material: Reaction sintering / Normal pressure sintering Silicon carbide

The wear-resistant ceramic lining corrugated compensator has efficient heat resistance, wear resistance, mechanical and thermal shock resistance, easy welding and installation, and is particularly suitable for material conveying pipelines that suffer from severe wear and scouring, such as those in the coal-fired power generation, metallurgy, coal, and mining industries. According to years of usage in the power, coal, and metallurgy industries, the service life of the ceramic wear-resistant lined pipe is ten times longer compared to ordinary seamless steel pipes, making it a replacement for cast stone pipes, alloy pipes, and organic material linings, thus being an ideal wear-resistant pipeline.

Performance characteristics: The lining ceramic is an integral sintered industrial ceramic with good wear resistance; it solves the defect of the ceramic tiles of the patch ceramic compensator easily falling off; it also addresses the issues of cracks and peeling in self-combustion ceramics; the outer pipe is a seamless steel pipe with strong pressure-bearing capacity and long conveying distance; it is relatively lightweight, making installation easy; elbows, tees, and reducers can be customized according to user requirements; connections can be made using flanges, welding, or active joints.

Therefore, the application of ceramic wear-resistant corrugated compensators in engineering wear areas is not only used in coal-fired power plants for ash removal, slag discharge pipes, powder delivery, and return powder pipes, and desulfurization pipelines, but also widely used in the following industries: Mining: Coal slurry, washed coal mud, mining filling materials, and coal powder in the coal industry; Metal mining: Wear-resistant elbows for the transportation of concentrates and tailings; At the same time, wear-resistant ceramic corrugated compensators are used in metallurgy: pipelines for coal injection in ironmaking blast furnaces and slag transportation in steel plants; CAO, zinc sand transportation pipelines, and preferred wear-resistant corrugated compensators for transporting ferroalloys and refining outside the furnace; In cement plants, the usage characteristics of wear-resistant ceramic corrugated compensators include the transportation of raw slurry in wet rotary kiln production lines, coal powder transportation, discharge from elevators, pneumatic conveying and unloading of finished cement, and wear-resistant elbows for concrete transportation. Chemical plants: Coal powder transportation pipelines, and wear-resistant corrugated compensators for transporting raw materials such as silicon powder.

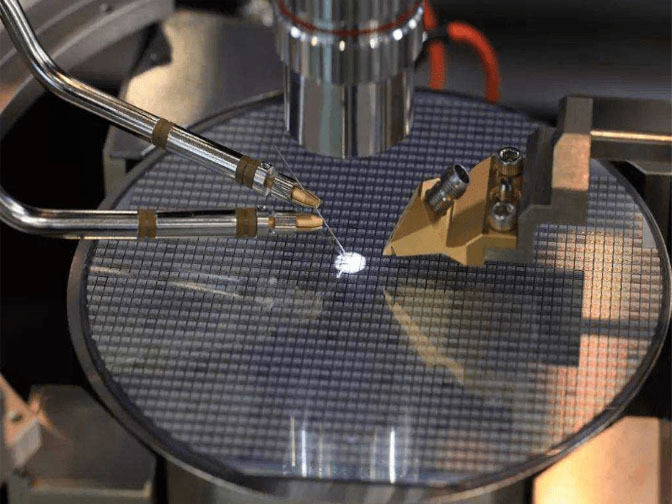

Wear-resistant and corrosion-resistant

Wear-resistant lining for mines

Material: Reaction sintering / Normal pressure sintering Silicon carbide

The wear-resistant ceramic lining corrugated compensator has efficient heat resistance, wear resistance, mechanical and thermal shock resistance, easy welding and installation, and is particularly suitable for material conveying pipelines that suffer from severe wear and scouring, such as those in the coal-fired power generation, metallurgy, coal, and mining industries. According to years of usage in the power, coal, and metallurgy industries, the service life of the ceramic wear-resistant lined pipe is ten times longer compared to ordinary seamless steel pipes, making it a replacement for cast stone pipes, alloy pipes, and organic material linings, thus being an ideal wear-resistant pipeline.

Performance characteristics: The lining ceramic is an integral sintered industrial ceramic with good wear resistance; it solves the defect of the ceramic tiles of the patch ceramic compensator easily falling off; it also addresses the issues of cracks and peeling in self-combustion ceramics; the outer pipe is a seamless steel pipe with strong pressure-bearing capacity and long conveying distance; it is relatively lightweight, making installation easy; elbows, tees, and reducers can be customized according to user requirements; connections can be made using flanges, welding, or active joints.

Therefore, the application of ceramic wear-resistant corrugated compensators in engineering wear areas is not only used in coal-fired power plants for ash removal, slag discharge pipes, powder delivery, and return powder pipes, and desulfurization pipelines, but also widely used in the following industries: Mining: Coal slurry, washed coal mud, mining filling materials, and coal powder in the coal industry; Metal mining: Wear-resistant elbows for the transportation of concentrates and tailings; At the same time, wear-resistant ceramic corrugated compensators are used in metallurgy: pipelines for coal injection in ironmaking blast furnaces and slag transportation in steel plants; CAO, zinc sand transportation pipelines, and preferred wear-resistant corrugated compensators for transporting ferroalloys and refining outside the furnace; In cement plants, the usage characteristics of wear-resistant ceramic corrugated compensators include the transportation of raw slurry in wet rotary kiln production lines, coal powder transportation, discharge from elevators, pneumatic conveying and unloading of finished cement, and wear-resistant elbows for concrete transportation. Chemical plants: Coal powder transportation pipelines, and wear-resistant corrugated compensators for transporting raw materials such as silicon powder.