Ceramic industry

Beams, rollers, burners, used for ceramic kilns;

Material: Reaction-sintered silicon carbide/nitride silicon bonded silicon carbide

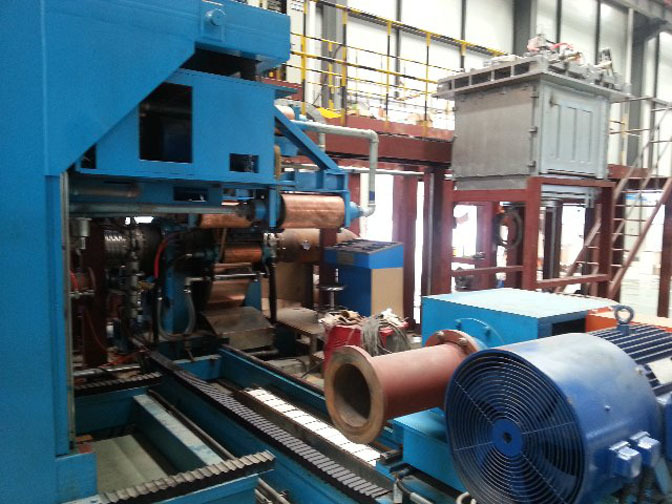

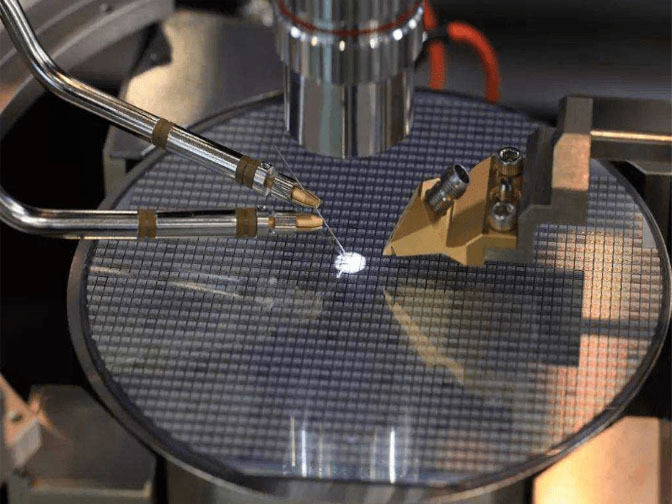

Roller kilns are a type of kiln with high output and low energy consumption, initially used in the building ceramics, sanitary ceramics, and daily-use porcelain industries. Due to its many advantages and the development of roller materials, such as the emergence of silicon carbide ceramic rollers, it has begun to be used in the lithium battery materials, rare earth, magnetic materials raw materials, electronic powders, and electrical porcelain parts industries in the past two years. The emergence of silicon carbide rollers allows the furnace temperature to reach as high as 1200℃.

Electric heated roller kilns are lightweight continuous industrial kilns, widely used for the rapid firing of ternary cathode materials, chemical powders, ceramic substrates, and other products. They have advantages such as low energy consumption, short firing cycles, good temperature uniformity, and low labor intensity. Roller kilns are kiln equipment for firing lithium battery powder materials, suitable for sintering powder materials in an oxidizing atmosphere.

Ceramic industry

Beams, rollers, burners, used for ceramic kilns;

Material: Reaction-sintered silicon carbide/nitride silicon bonded silicon carbide

Roller kilns are a type of kiln with high output and low energy consumption, initially used in the building ceramics, sanitary ceramics, and daily-use porcelain industries. Due to its many advantages and the development of roller materials, such as the emergence of silicon carbide ceramic rollers, it has begun to be used in the lithium battery materials, rare earth, magnetic materials raw materials, electronic powders, and electrical porcelain parts industries in the past two years. The emergence of silicon carbide rollers allows the furnace temperature to reach as high as 1200℃.

Electric heated roller kilns are lightweight continuous industrial kilns, widely used for the rapid firing of ternary cathode materials, chemical powders, ceramic substrates, and other products. They have advantages such as low energy consumption, short firing cycles, good temperature uniformity, and low labor intensity. Roller kilns are kiln equipment for firing lithium battery powder materials, suitable for sintering powder materials in an oxidizing atmosphere.