Energy saving and environmental protection

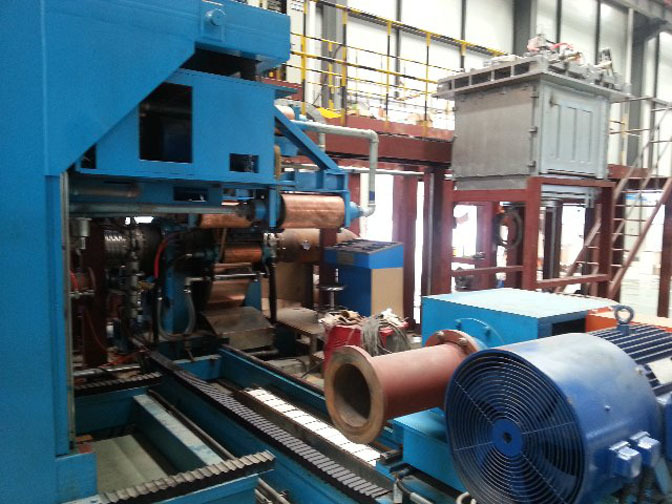

Flue Gas Desulfurization System Atomizing Nozzle

Material: Reaction Sintered/Nitride Silicon Bonded Silicon Carbide

The desulfurization atomizing nozzle made of reaction sintered silicon carbide (SISIC) has a service life several times to over a dozen times longer than other materials. Reaction sintered silicon carbide (SISIC) represents a more advanced level of material in the field of desulfurization nozzles today. This nozzle has extremely strong wear resistance and corrosion resistance, operating continuously for years without significant wear, providing an ultra-long service life. It is an ideal material for making desulfurization nozzles. To better serve our customers, our company has established a performance testing platform for desulfurization nozzles, which can test the flow rate, pressure, injection angle, and other performance metrics of the nozzles, providing customers with reliable and satisfactory products. Our company's nozzle design is reasonable, with a smooth inner cavity surface that does not hang slurry, good liquid atomization effect, and excellent anti-blocking performance.

Desulfurization nozzles are used in power plants for desulfurization, removing sulfur dioxide and some pollutants from the flue gas.

The flue gas from coal-fired power plants and the gas in combined cycle gas (for gas turbine combustion) have a common task, which is desulfurization and denitrification (of course, also dust removal). The flue gas discharged from power plants without desulfurization and denitrification directly pollutes the atmospheric environment, while the gas in combined cycle without purification treatment can harm the hot end components of the gas turbine. Its exhaust will also pollute the environment.

Energy saving and environmental protection

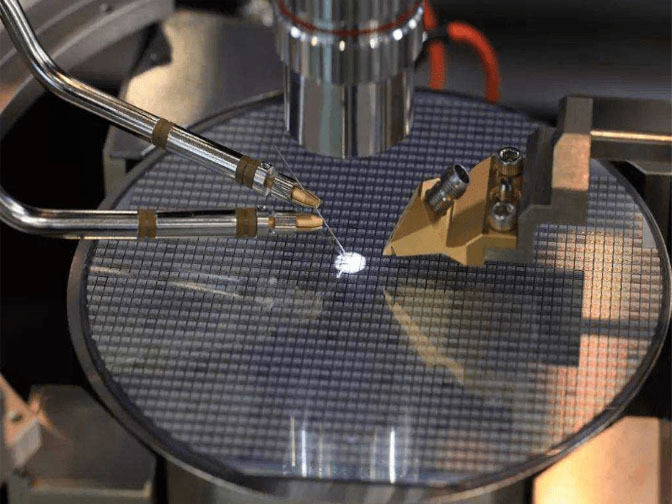

Flue Gas Desulfurization System Atomizing Nozzle

Material: Reaction Sintered/Nitride Silicon Bonded Silicon Carbide

The desulfurization atomizing nozzle made of reaction sintered silicon carbide (SISIC) has a service life several times to over a dozen times longer than other materials. Reaction sintered silicon carbide (SISIC) represents a more advanced level of material in the field of desulfurization nozzles today. This nozzle has extremely strong wear resistance and corrosion resistance, operating continuously for years without significant wear, providing an ultra-long service life. It is an ideal material for making desulfurization nozzles. To better serve our customers, our company has established a performance testing platform for desulfurization nozzles, which can test the flow rate, pressure, injection angle, and other performance metrics of the nozzles, providing customers with reliable and satisfactory products. Our company's nozzle design is reasonable, with a smooth inner cavity surface that does not hang slurry, good liquid atomization effect, and excellent anti-blocking performance.

Desulfurization nozzles are used in power plants for desulfurization, removing sulfur dioxide and some pollutants from the flue gas.

The flue gas from coal-fired power plants and the gas in combined cycle gas (for gas turbine combustion) have a common task, which is desulfurization and denitrification (of course, also dust removal). The flue gas discharged from power plants without desulfurization and denitrification directly pollutes the atmospheric environment, while the gas in combined cycle without purification treatment can harm the hot end components of the gas turbine. Its exhaust will also pollute the environment.